PERFEKTION HAT EINEN NAMEN.

WIR SIND INNOVATIV.

AUS TRADITION.

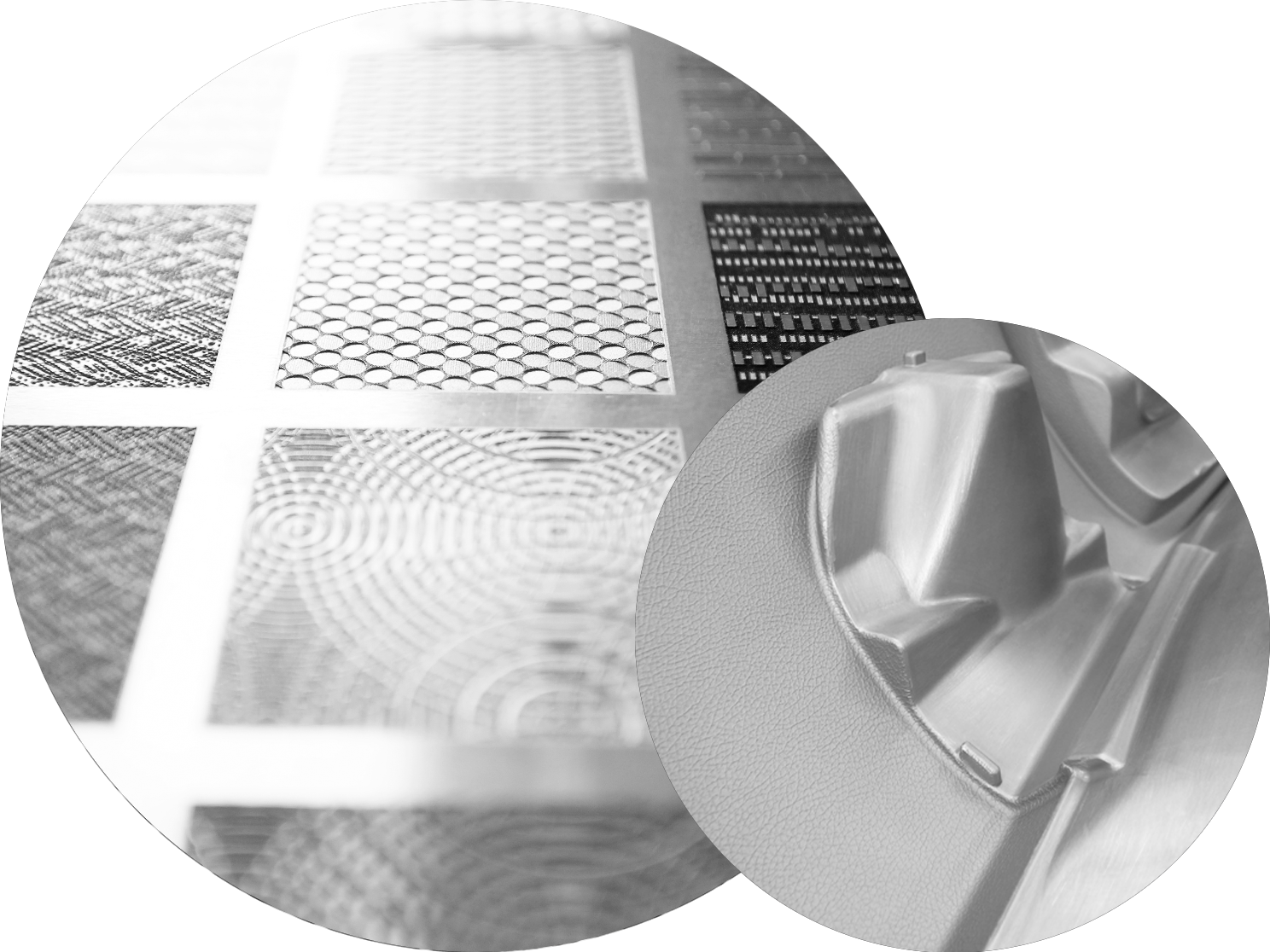

Traditionell wurden schmückende Dekore von Damaszierern in Werkstücke geätzt. Mit der Gründung von KRÜTH wurde diese Technik genutzt, um Werkstücke für unterschiedlichste Einsatzbereiche mit dekorativen Gravuren zu versehen.

Seit ca. 1950 werden die Oberflächen von Spritzgieß-Werkzeugen geätzt und mit Gravuren versehen, um in einem anschließenden Abform-Prozess Kunststoff-Bauteile herzustellen. Heute werden mit modernsten Technologien innovative Gravuren, Symbole und Beschriftungen in die Oberflächen von Werkzeugen eingebracht.

Schon im Mittelalter wurden in Solingen von Schmieden Versuche unternommen, Oberflächen durch den Ätz- Prozess zu veredeln. Der hochwertige Stahl stammte ursprünglich aus Damaskus und wurde für Klingen von Schwertern und Dolchen eingesetzt und im Anschluss verziert. Dieser sogenannte Damaszenerstahl besteht aus mehreren Lagen miteinander verschweißter Stähle in unterschiedlicher Art und Härte.

Doch erst durch den Ätz-Prozess in speziellen Säuren wurden die geschichteten Stahllagen sichtbar. Die einzelnen Stähle verfärbten sich durch den Einfluss von Säure unterschiedlich.

Die auf Degen, Rüstungen, Schwertern, Dolchen und ähnlichem Kriegswerkzeug eingeätzten Schriften, Ornamente und Symbole bewiesen die Einzigartigkeit der Kampfausrüstung und kennzeichneten die Zugehörigkeit zum Ritterstand.

2020

Expansion des Maschinenparks (Laser- & Druckermaschinen)

2019

Eröffnung des Zweigwerks am Dahl

2017

Gründung der Global Laser Group (GLG) www.globallasergroup.com

2015

Produktionsstandort Portugal

2014

Hochauflösende Scanner Station

2013

Zweite Lasermaschine für Großwerkzeuge

2011

Erste Lasermaschine für Großwerkzeuge über 3,5 t

2007

Abteilung Laser-ÄtzGravur und 3D-LaserGravur

2005

Auszeichnung „Lebendige Unternehmenskultur“ Eigentümer der SET Form-Ätz-Technik

2000

ÄtzGravur mit 2-Glanz Abteilung NiOn100 und NiOn200

1998

Eröffnung KRÜTH do Brasil, São Bernardo bei São Paulo

1994

Porcerax II® ausgezeichnet v. jap. Industriebehörde (MITI) Übernahme „Vereinigten Werkstätten“ KRÜTH und Int. Mold Steel gründen KRÜTH IMS

1992

Mono- und 2-Glanz-Veredelung von Nickelschalen

1990

ÄtzGravur mit Multilayer-Filmen

1969

Gründung der Firma KRÜTH

1960

ÄtzGravur, erste Stahl-Werkzeuge

KREATIVITÄT ERFORDERT DEN MUT, SICHERHEITEN LOSZULASSEN.

– Erich Fromm –

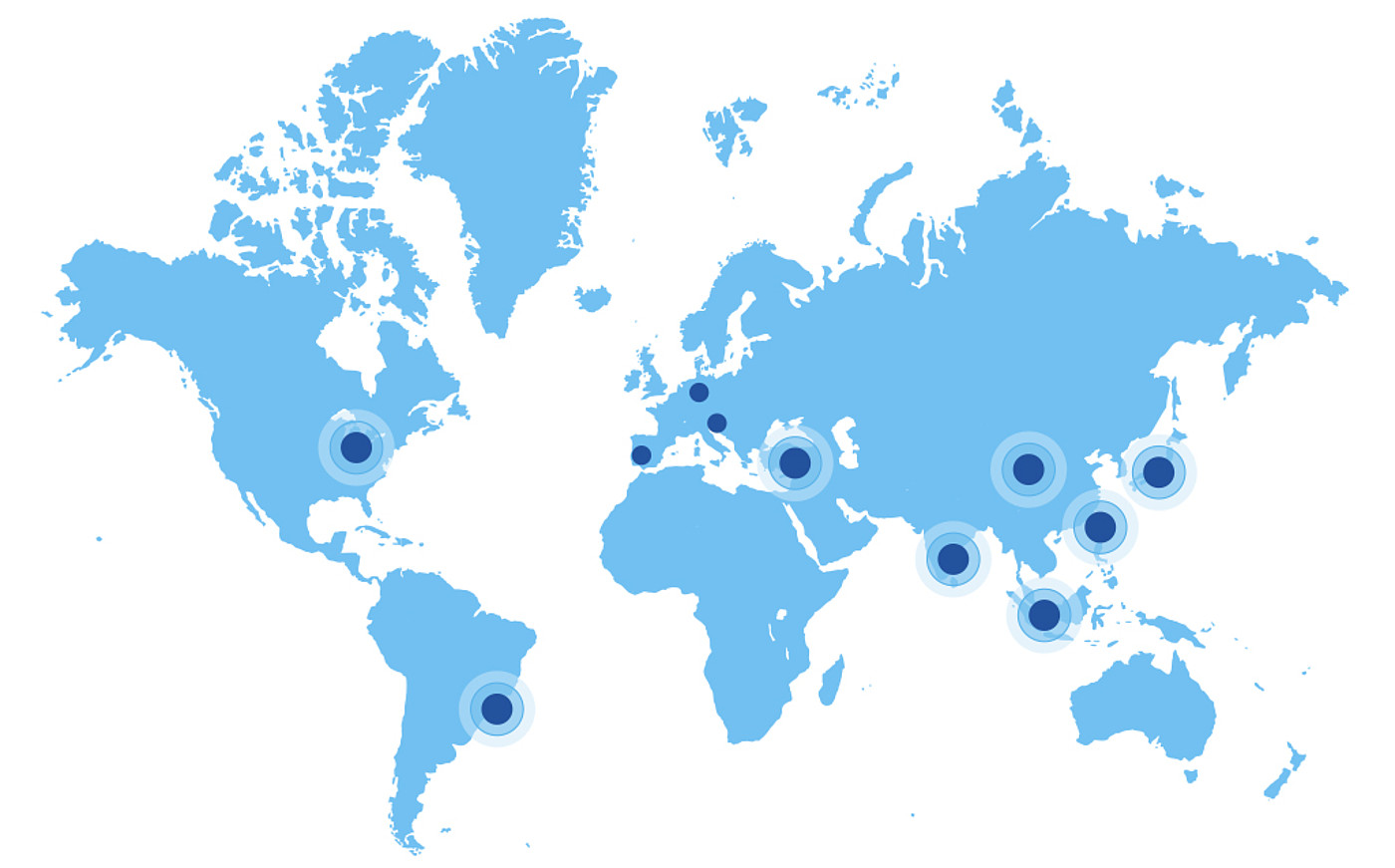

KRÜTH GLOBAL

SEC WELTWEIT

KRÜTH ist über das weltweite Netzwerk SEC (Surface Etching Cooperation) mit der Technologie ÄtzGravur in Europa, Amerika und Asien international vertreten.

GLG WELTWEIT

Die GlobalLaserGroup, wurde gegründet um Kunden weltweite Unterstützung in der 3D-LaserGravur Technologie zu bieten.

SET KRÜTH AUSTRIA

Seit über 20 Jahren bearbeitet die Tochterfirma SET-KRÜTH Oberflächen für Druck- und Spritzgussformen. Werkzeugoptimierungen, Service zu Formen, sowie Polier-Arbeiten und Reparaturschweißungen werden ebenfalls durchgeführt.

KRÜTH PORTUGAL

KRÜTH unterhält hier seit Anfang 2015 ein zweites Tochterunternehmen.

EIN AUSZUG DER KRÜTH REFERENZEN

BASF COVESTRO BIA ZWILLING ERCO BRAUN GIRA HELLA HEYCO EMSA GEELY ADIDAS VORWERK WILKHAHN KOSTAL WILKINSON TRW AUTOLIV JOYSON SAFETY SYSTEMS AUDI BMW PORSCHE VW SKODA SEAT VOLVO SCANIA MERCEDES PSA RENAULT OPEL TUPPERWARE MIELE JAGUAR FORD NIO YANGFENG FIAT ADIENT FAURECIA GRUPO ANTOLIN …

JOBS

Sie möchten sich beruflich neu orientieren?

Wir freuen uns immer über spannende und aussagekräftige Bewerbungen.

WAS WIR BIETEN

Ein kompetentes Team aus jungen und langjährigen Mitarbeitern stellt sich jeden Tag neuen Herausforderungen, um den Wünschen unserer Kunden zu entsprechen. Unsere Ansprechpartner sind sowohl OEMs als auch TIERs.

Das harmonische Arbeitsklima in einem dynamischen Umfeld erfordert Teamfähigkeit und das Einbringen von eigenen Ideen. Zu unseren Work-Life-Balance-Angeboten gehören das Fahrradleasing, täglich frisches Obst und regelmäßige ausgefallene Firmenevents. Zusatzleistungen wie Urlaubs- und Weihnachtsgeld, Vermögenswirksame Leistungen, Direktversicherung mit Arbeitgeber Bezuschussung und eine leistungsgerechte Bezahlung sind für uns selbstverständlich. Bei unseren Tochterfirmen sind Kurzprojekte (2 – 3 Wochen) im Ausland möglich.

AKTUELLE STELLENANGEBOTE

Eine ausführliche Beschreibung unserer aktuellen Stellen finden Sie im PDF-Download.

Aktuell sind alle Stellen bei uns besetzt.

Wir freuen uns immer über Initiativbewerbungen.

AUSBILDUNG

Hallo! Ich bin Sebastian, Auszubildender bei KRÜTH.

Du hast gerade deinen Schulabschluss, dein Studium oder bereits eine Ausbildung abgeschlossen und interessierst dich für Design, Formen und Oberflächenstrukturen? Dann hast du bei uns die Chance den Künstler oder Techniker in dir zu entdecken.

DEINE ZUKUNFT

BEI KRÜTH

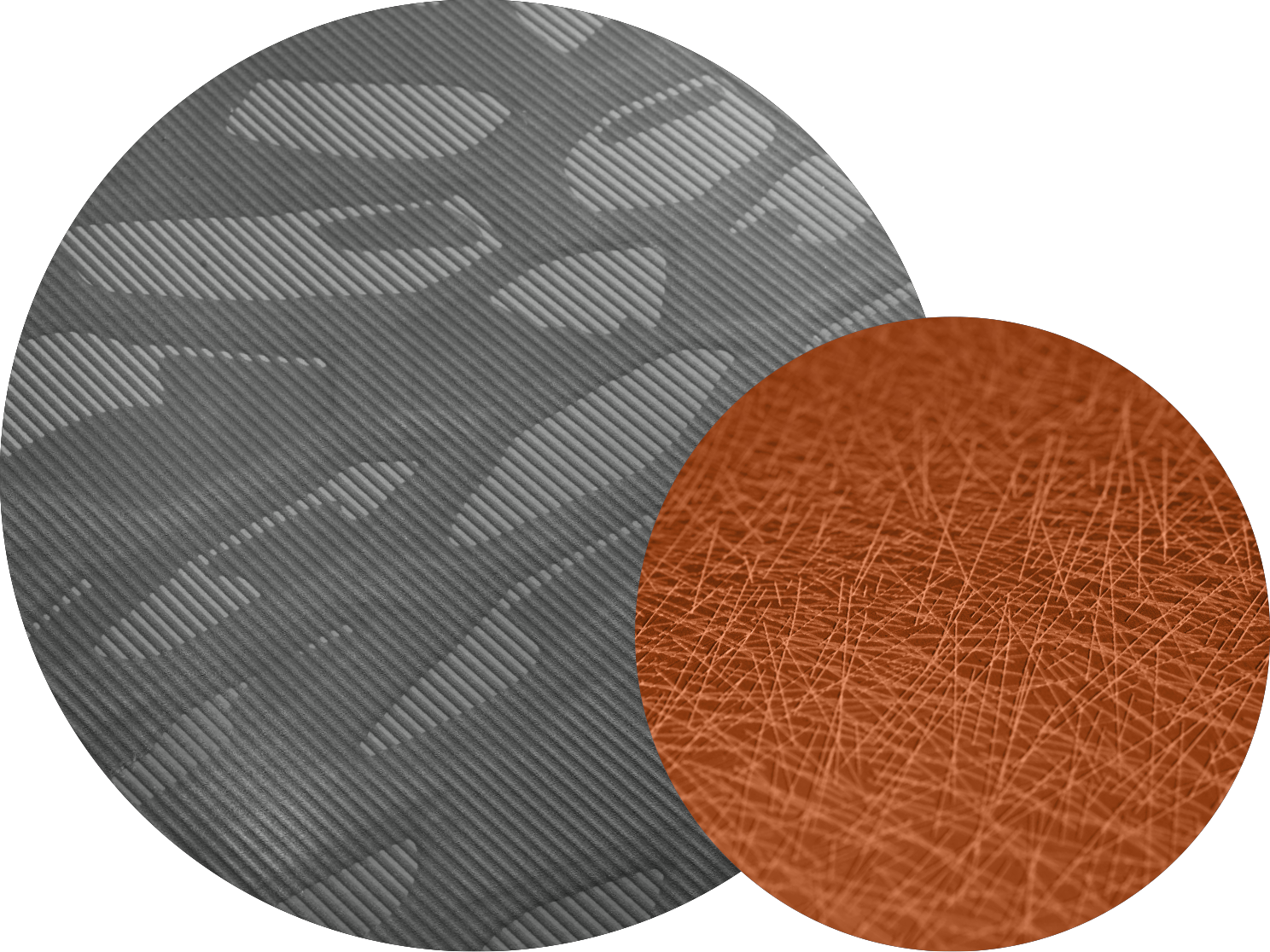

WAS DU LERNST

Du erlernst den Umgang und die Bearbeitung von Stahl- und Aluminium-Werkzeugen. Diese sind Negativ-Formen, z.B. für Spritzguss-Bauteile der Automobilindustrie. Zu deinen Tätigkeiten gehören das Reinigen und Abdecken der Formen, sowie das Einbringen der Oberflächenstrukturen. Dies geschieht durch die Bearbeitung von Hand oder mit dem Laser. Das Einstellen von Oberflächenglanz durch Glas- und/oder Sandstrahlen schließt den Prozess ab.

Das Designen und Entwickeln von neuen Strukturen stärkt deine kreative Ader. Das Bedienen unterschiedlicher Maschinen fördert dein technisches Geschick und erweitert dein Fachwissen.

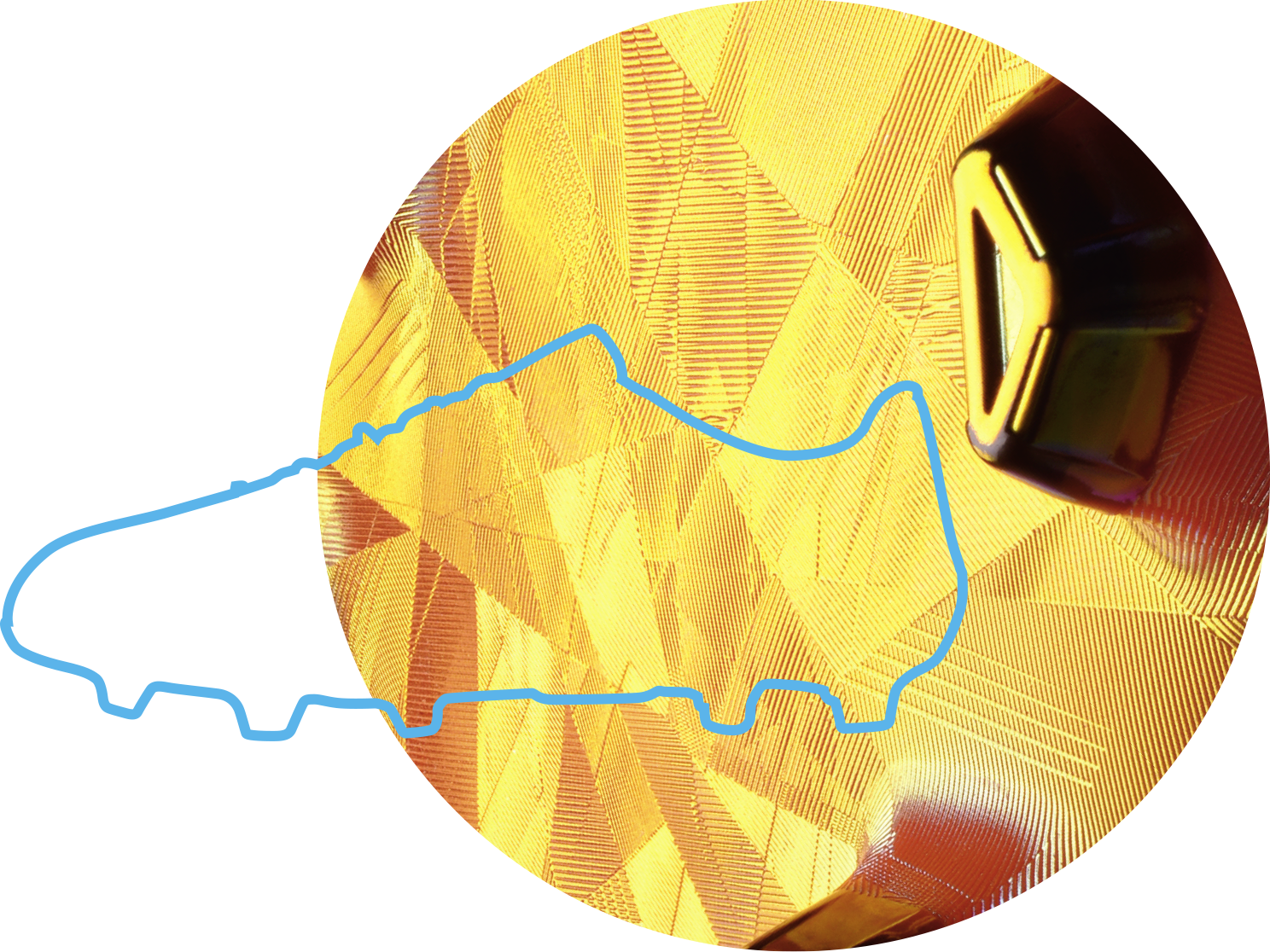

Bei uns kannst du den WM-Schuh designen und dir den Weltmeistertitel verdienen oder die Oberflächenstrukturen der Fahrzeuge von Morgen entwickeln.

Die Kollegen und Ausbilder sind sehr hilfsbereit und fördern dich individuell.

DER GRAVEUR BERUF

Der Graveur mit der Fachrichtung „Flachgravur“ bringt eine Gravur in Metall, Glas und auch Kunststoff spanabhebend, durch Ätzung oder durch einen Laser ein.

Damals waren Damaszierer die Metallkünstler. Im Laufe der Jahrhunderte wurden statt Waffen immer mehr Schneidwerkzeuge und Bestecke mit kunstvollen Schnörkel oder Rankenmuster durch Gravuren und/oder Ätzungen verziert.

Heute werden Kalligrafie, Typografie, Baustile- und Designentwicklung, sowie das Zeichnen mit Tusche und Bleistift, gelehrt. Der Umgang mit dem PC gehört zum beruflichen Standard.

KRÜTH fördert neben der Ausbildung die Teilnahme an Kursen, um z.B. die zeichnerischen Fähigkeiten zu erweitern. Die gesamte Ausbildung schließt mit dem Gesellenbrief zum Industrie-Graveur ab.

Du bist dir nicht sicher, ob Graveur zu dir passt?

Dann erfahre einen Einblick in die verschiedenen Bereiche bei einem Schnuppertag in unserem Unternehmen!

JETZT

BEWERBEN

AUSBILDUNGSDAUER

Ausbildung 3 Jahre

verkürzt 2,5 Jahre

BERUFSKOLLEG

Blockunterricht

in Solingen

URLAUB

30 Tage im Jahr

AUSBILDUNGSFORM

Dual = Betrieb + Schule

GRAVEUR Schwerpunkt

FLACHGRAVIERTECHNIK

(Ätzen + 2D/3D Lasern)

WEITERBILDUNG

Interne Weiterbildung

Graveur-Meister

Gestaltungstechniker/in

Studium für Gestaltung

VERGÜTUNG

1. Jahr = 750,– EUR

2. Jahr = 780,– EUR

3. Jahr = 835,– EUR

(gem. Vertrag m.d. IG Metall)

JETZT BEWERBEN

ALS

METALLTÄTOWIERER

ODER LASERQUEEN

Hallo, ich bin Julia. Ich bin Graveurin.

Nachdem ich meine Abschlussprüfung absolviert habe wurde ich von KRÜTH übernommen und arbeite jetzt in meinem Lieblingsbereich.

Intern gibt es viele Weiterbildungsmöglichkeiten.

Für meine Zukunft plane ich in einem der KRÜTH Tochterunternehmen Auslandserfahrungen zu sammeln und meine Sprachkenntnisse fachlich zu verbessern. Mir macht meine Arbeit sehr viel Freude, denn meine Leidenschaft zum Detail ist für meinen Beruf ein klares Plus.

Schaue dir unser Azubi-Video an!

Scanne einfach den QR-Code in der Abbildung.

JETZT

BEWERBEN