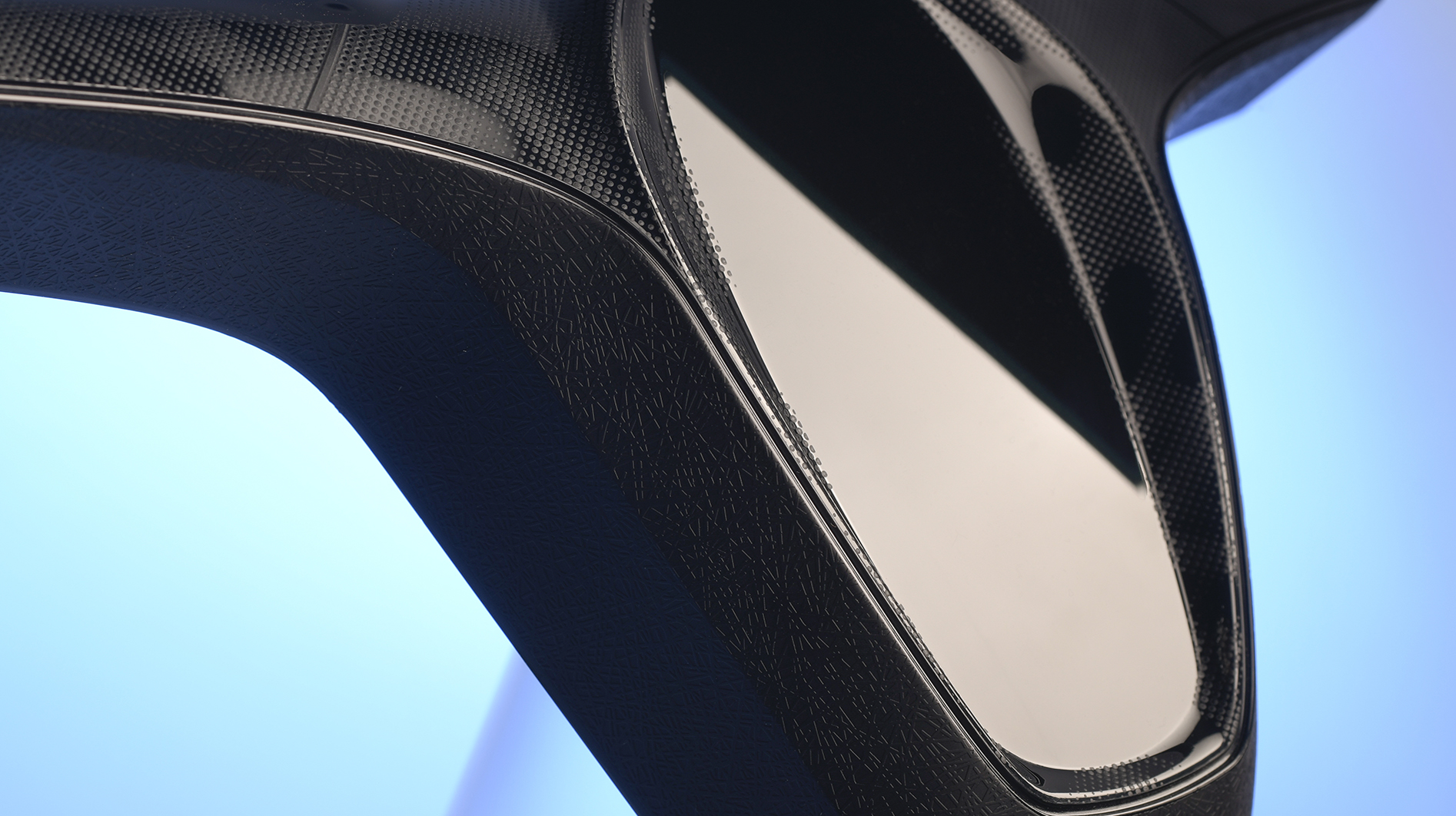

High gloss and precise engraving in a single component.

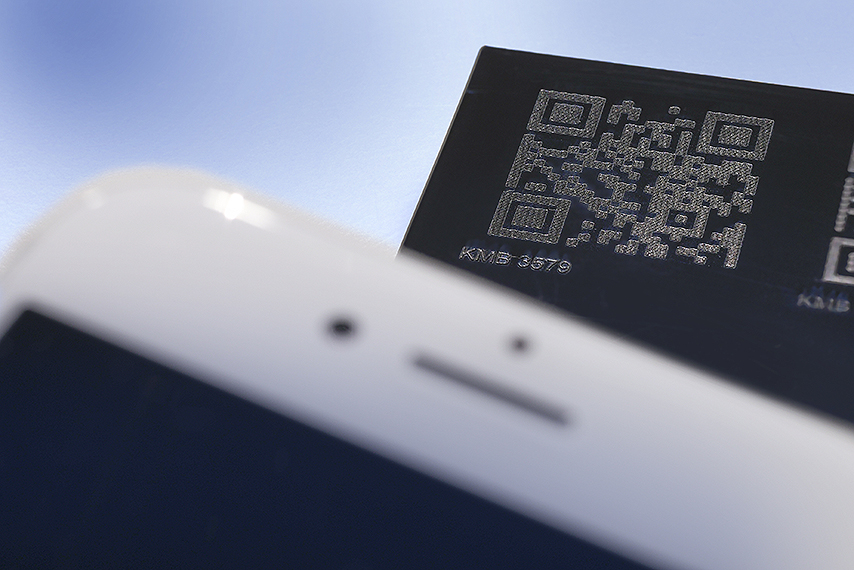

As beautiful as engravings can be, engraved and non-engraved areas alternate in terms of design. These must then be effectively protected during tool processing. Technologically, 3D-LaserEngraving is at the forefront here when signets or logos need a high gloss finish or entire surfaces need to be exposed as structural elements. They can also be functional surfaces that are precisely designed for stickers. Cuts and markings can be produced according to individual CAD data. A mirror-like high-gloss surface also requires special protection during the laser process. This calls for great precision, which digital engraving can achieve with micrometer accuracy.

When it comes to engravings and the exact boundaries to other surfaces, KRÜTH knows where to draw them.