QUALITY DEPARTMENT

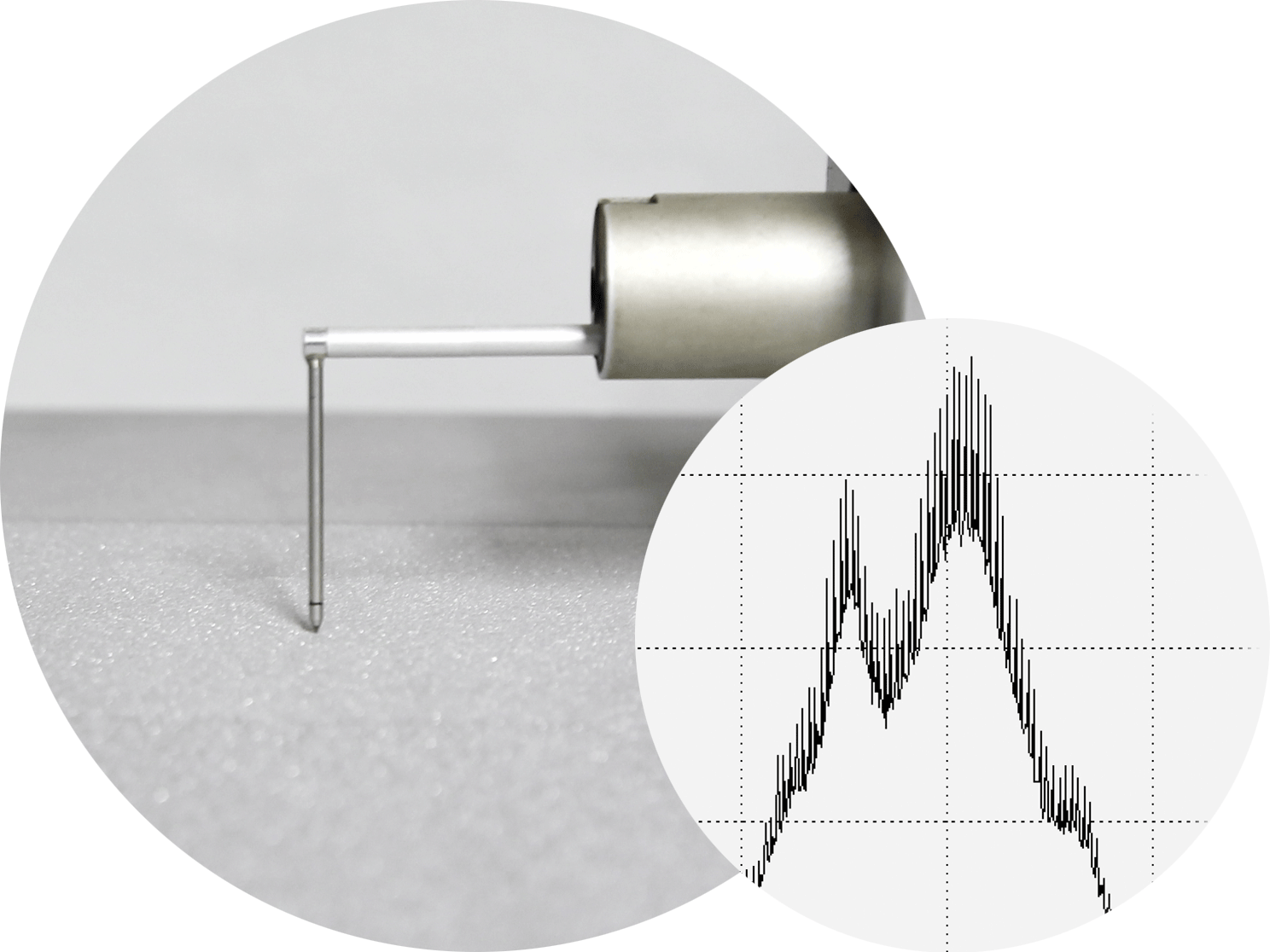

IT CAN’T BE ANY MORE ACCURATE – THE PERFECT IMAGE.

It is often the nearly invisible details that are nonetheless decisive for the surface’s overall impression. Precise monitoring and ongoing comparison with the engraved surfaces ensure that all the parameters – in terms of the structure, roughness, depth of the grain, and gloss – are retained throughout the entire manufacturing process.