WE ARE INNOVATIVE.

AS A MATTER OF TRADITION.

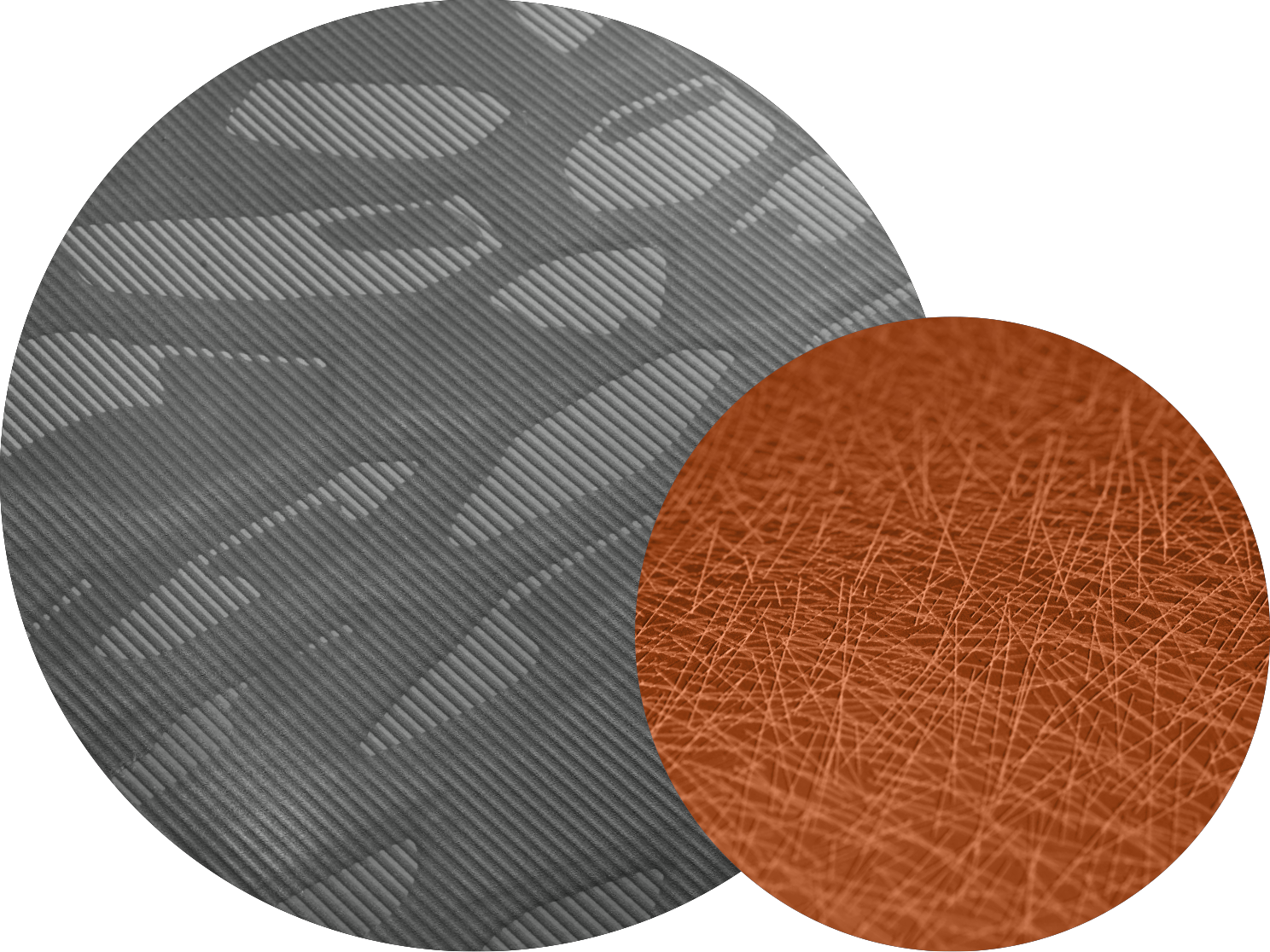

Traditionally, ornaments were etched in workpieces by damascening. When KRÜTH was founded, this technique was used to lend decorative structures to the tools that were intended for a wide variety of purposes.

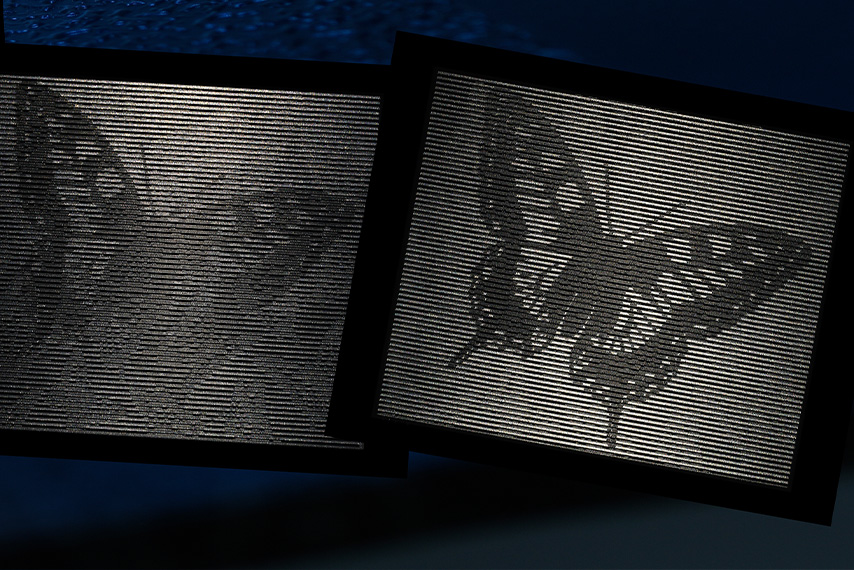

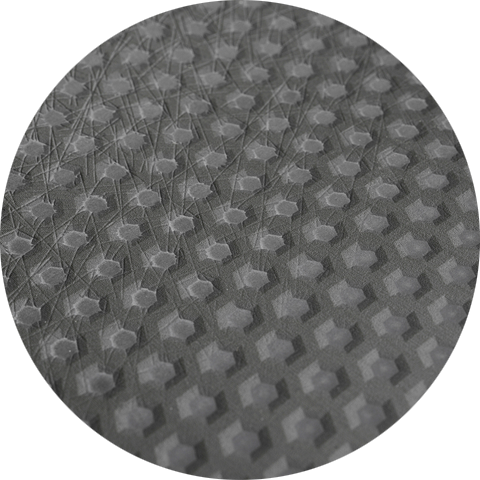

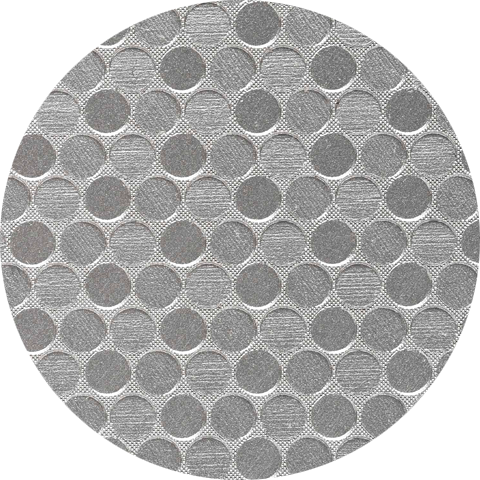

Since about 1950, the surfaces of injection molds were etched and provided with engravings so that plastic parts could be manufactured in a subsequent casting process. Today, using the most modern technology, innovative engravings, symbols, emblems, and lettering are imprinted on the surfaces of such tools.

Even in the Middle Ages, blacksmiths in Solingen experimented with using etching to finish surfaces. The high-quality steel originated in Damascus. This steel was used for the decorated blades of swords and daggers. Damascus steel comprised multiple layers of steels, varying in alloy and hardness, which were then welded together.

But only with the etching process, using special acids, did the stacked layers of steel become visible. The individual steel alloys responded differently to the acid used here.

The lettering, ornaments and symbols etched on sabers, armor, swords, daggers and other instruments of war demonstrated the singularity of the arms and indicated that the wearer was a member of the knighthood.

2020

Expansion of machinery (laser- & printing machines)

2019

Opening of the branch on Dahl

2017

Foundation of the Global Laser Group (GLG) www.globallasergroup.com

2015

Production site opened in Portugal

2014

High-resolution scanner technology

2013

Second laser for large molds

2011

First laser machine for molds exceeding 3.5 t

2007

Department opened for Laser-EtchingEngraving and 3D-LaserEngraving

2005

Presentation of the “Living Corporate Culture” award Took over the company SET Form-Ätz-Technik

2000

EtchingEngraving with double-gloss Electroplating department for NiOn100 and NiOn200

1998

Launch of KRÜTH do Brasil in São Bernardo, near São Paulo

1994

Porcerax II® lauded by the Japanese Ministry of International Trade and Industry (MITI) Takeover of the “Vereinigten Werkstätten” KRÜTH IMS founded by KRÜTH and Int. Mold Steel

1992

Mono- and double-gloss finishing of nickel shells

1990

EtchingEngraving with multilayer films

1969

Founding of the KRÜTH company

1960

EtchingEngraving; first steel molds

SEC WORLDWIDE

KRÜTH operates through its worldwide SEC (Surface Etching Cooperation) network internationally with the technology EtchinEngraving.

GLG WORLDWIDE

GLG, the GlobalLaserGroup, has been established to provide customers around the world in 3D-LaserEngraving technique.

SET KRÜTH AUSTRIA

For more than 20 years now, a subsidiary known as SET-KRÜTH, headquartered in Fohnsdorf, Austria, has processed surfaces for die casting molds and injection molding tools. Also handled here are tool optimization, service on molds as well as polishing work and welding in the course of repairs.

KRÜTH PORTUGAL

KRÜTH has had a second subsidiary in Oliveira de Azeméis since the beginning of 2015.

EXTRACT FROM KRÜTH REFERENCES

BASF COVESTRO BIA ZWILLING ERCO BRAUN GIRA HELLA HEYCO EMSA GEELY ADIDAS VORWERK WILKHAHN KOSTAL WILKINSON TRW AUTOLIV JOYSON SAFETY SYSTEMS AUDI BMW PORSCHE VW SKODA SEAT VOLVO SCANIA MERCEDES PSA RENAULT OPEL TUPPERWARE MIELE JAGUAR FORD NIO YANGFENG FIAT ADIENT FAURECIA GRUPO ANTOLIN …

JOBS

You would like to change your professional career?

We are always looking forward to receive interesting and informative applicants.

WHAT WE OFFER

A qualified team of young and experienced employees sets itself new challenges every day to fulfil the wishes of our customers. Our business partners are OEMs as well as TIERs.

The working atmosphere is harmonious in a dynamic environment and requires team spirit and the contribution of own ideas. Our work-life-balance-offers include bicycle leasing, a daily selection of fresh fruit and regular and special company events. In addition, special payments such as holiday and Christmas bonuses as well as financial benefits, direct insurance with employer's subsidy and a performance-related salary are included. Short projects (2 to 3 weeks) abroad are possible at our subsidiary companies.

CURRENT JOB OFFERS

A detailed description of our current vacancies can be found in the PDF download:

Nothing for you? We are always happy to receive proactive applications.

Hello! I'm Sebastian, an apprentice at KRÜTH.

You have just finished school, your studies or already completed an education and you are interested in design, shapes and surface structures? If this applies to you, with us you have the chance to discover the artist or technician in you.

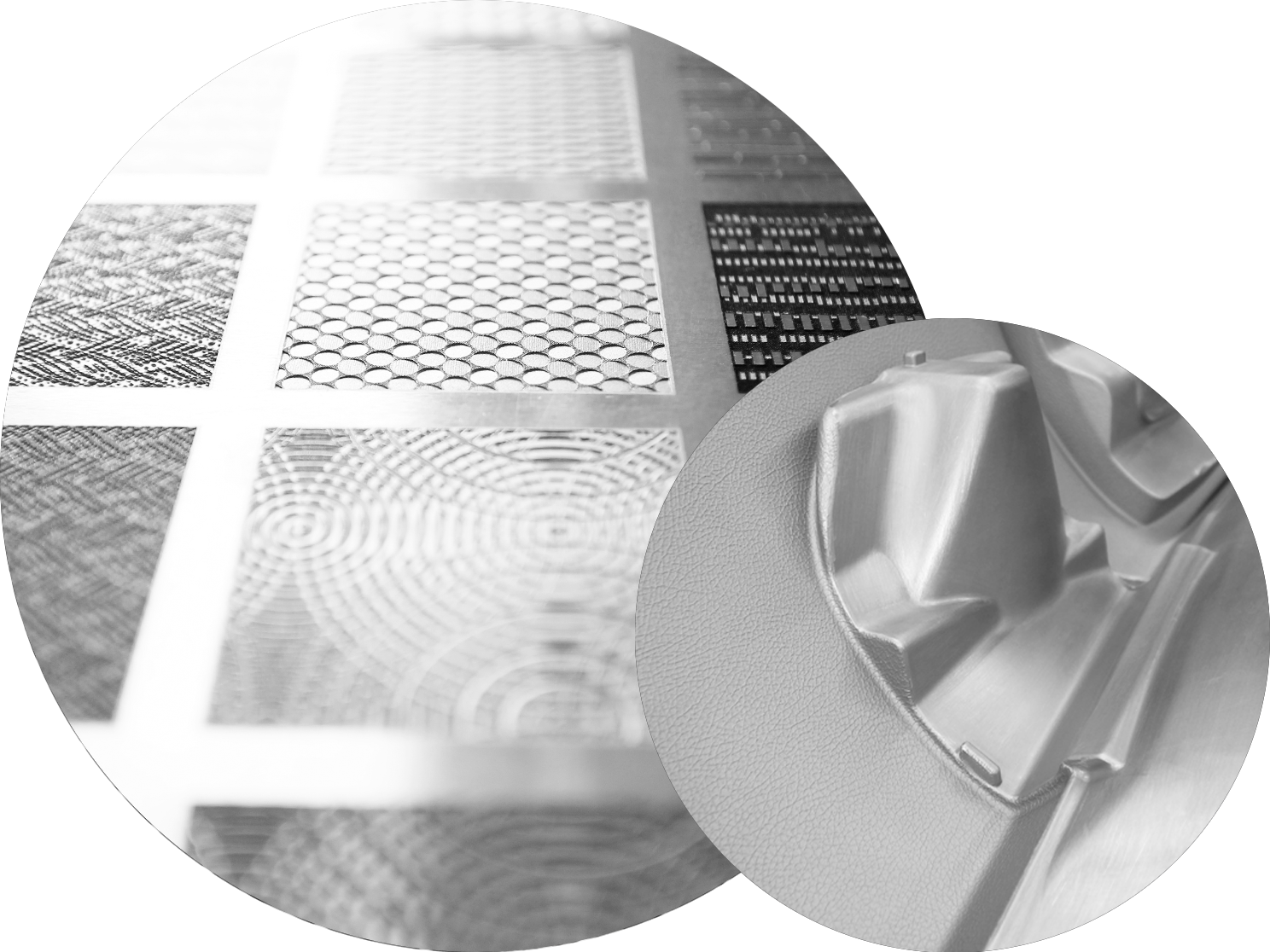

WHAT YOU LEARN

You learn how to handle and work with steel and aluminium tools. These are negative moulds, for injection-moulded components in e.g. the automotive industry. Your activities include cleaning and covering the moulds, as well as applying the surface structures. This is done by hand (manual) or with a lasermachines (automated). Adjusting the surface gloss by sandblasting completes the process.

The design and development of new structures gives your creative side a boost. Operating different machines will improve your technical skills and expand your knowledge.

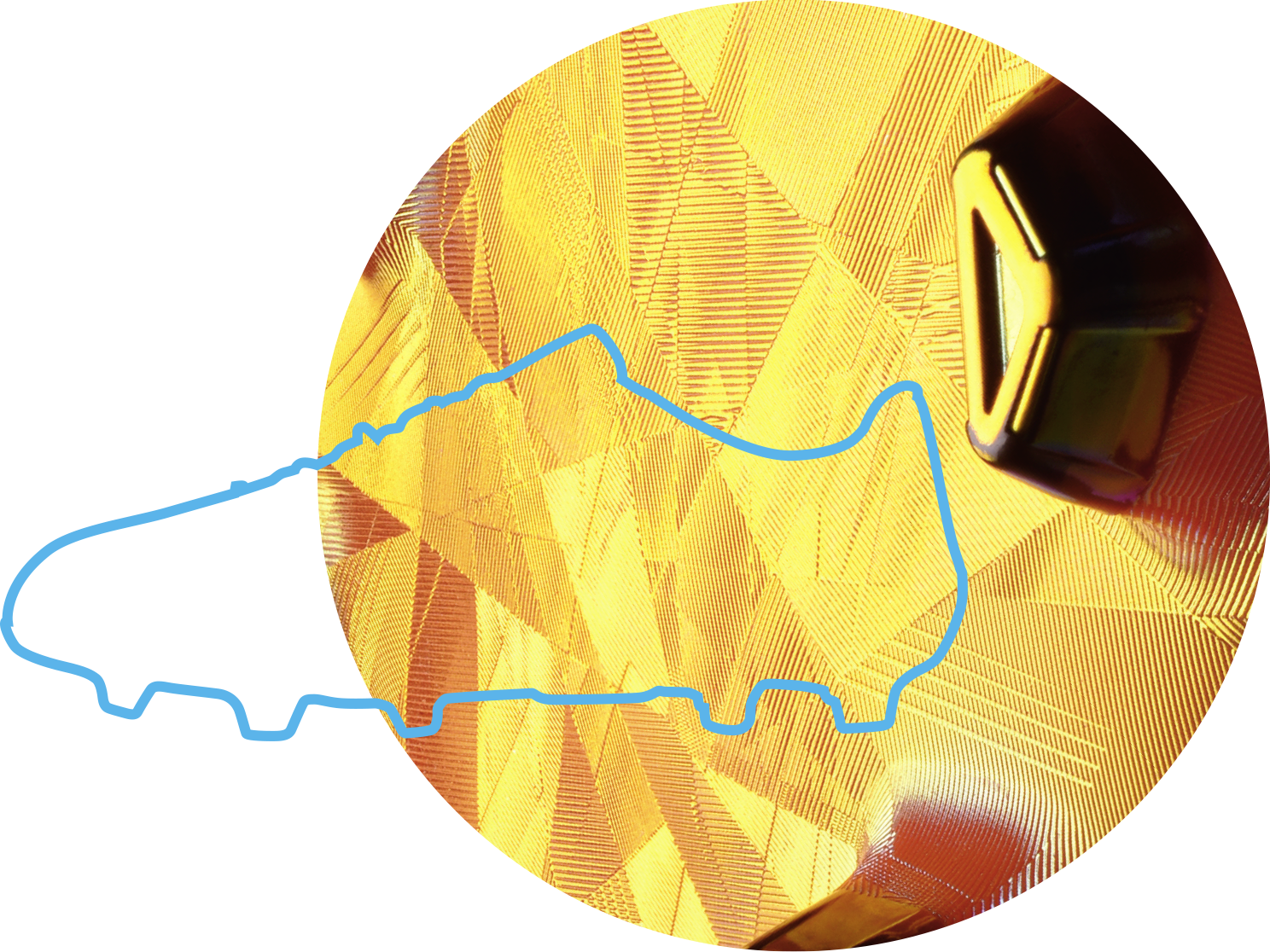

With us, you can design the world championship shoe and earn the world championship title or develop the surface structures of the vehicles of tomorrow.

The colleagues and trainers are very helpful and will support you individually.

THE ENGRAVER’S PROFESSION

The Engraver with the specialisation "flat engraving" applies an engraving in metal, glass and also plastic by mechanical processing, by etching or by lasering.

At that time, engraver were the metal artists. But over the centuries, instead of weapons, more and more cutting tools and cutlery were decorated with artful ornaments or floral patterns by engraving and/or etching.

Today, calligraphy, typography, the study of architectural styles and design development, as well as drawing with ink and pencil, are teached. The use of a PC is part of the professional standard.

In addition to the training, KRÜTH enriches the participation in courses, e.g. in improving the drawing skills. The entire training is completed with the qualification as an Industrial Engraver.