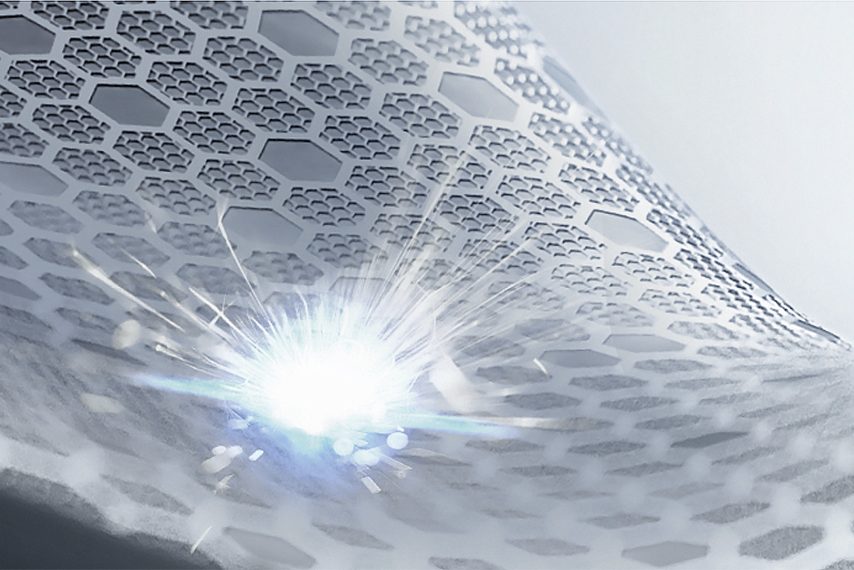

Precise 3D-LaserEngravings can be perfectly formed in parts from blow molds and used in the A-view area.

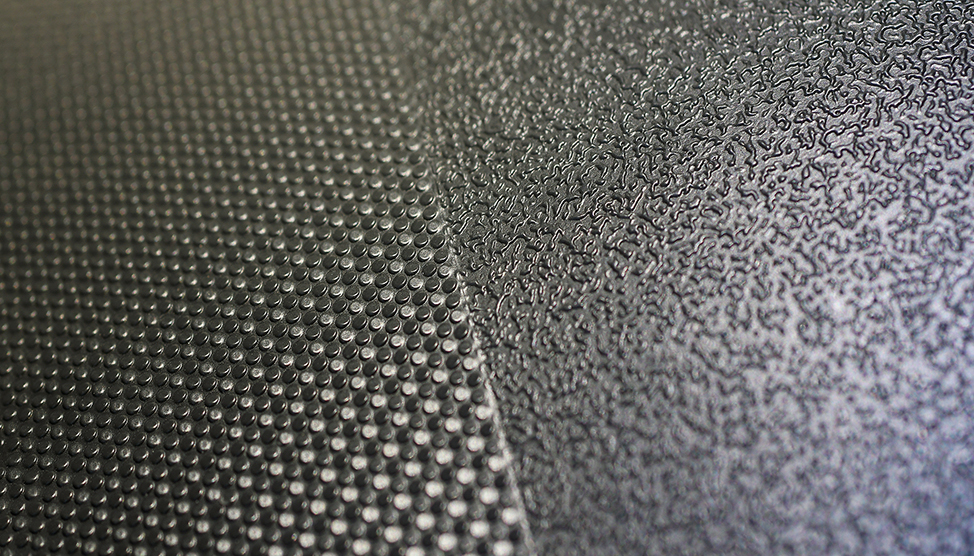

The use of blow molds in the production of plastics is the first choice when it comes to high economic quantities. 3D-LlaserEngraving is used to ensure that the highest level of surface quality is also possible in this process. Sharp-edged and detailed engravings can be carried out digitally and make it possible to compensate optically for production-related molding losses in series production. The engravings can also be lasered deeper in areas that are difficult to demold, in order to create a uniform image in the product. But even there are further purely technical advantages: vent holes in steel and aluminum molds could be specifically integrated into the design of the engraving. Technical properties such as flow behavior can be easily influenced by the use of fine, very round engravings.

Develop your quality requirements for blow molds with KRÜTH – suitable for your special applications.