The most important part of a coating is the clean preparatory work to ensure that components fit together perfectly when they are assembled.

Coated plastic surfaces present a special challenge, especially if a component is produced in series with and without a coating. Coating-friendly engravings can be developed in all technologies. The thickness of the coating and the coating system are key factors in developing the engraving. It is good if an engraving is developed from the outset that fulfils both criteria. For most series-produced components, however, two different variants are developed, one coated and one basic variant. For later assembly, the variants are placed next to each other to achieve a harmonious whole. Ergo: the right coated engraving ensures an excellent surface design. The adaptation to a foil can also be a task for engraving development. Here, too, the ultimate goal is to make sure that components fit together perfectly when they are assembled.

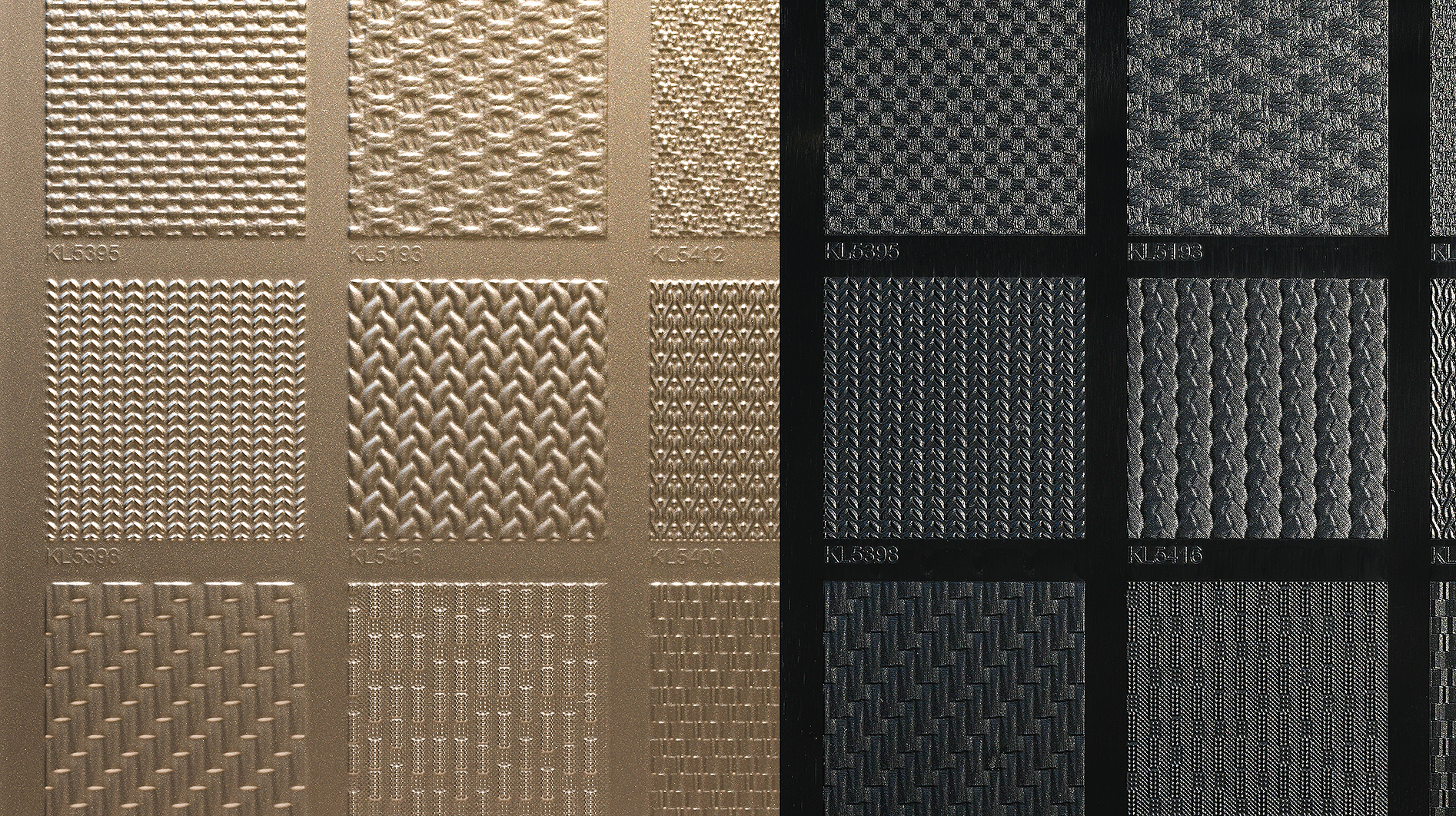

The ideal engraving development to match the coated plastic surface, as a result of the intensive cooperation with KRÜTH, is something to be proud of.