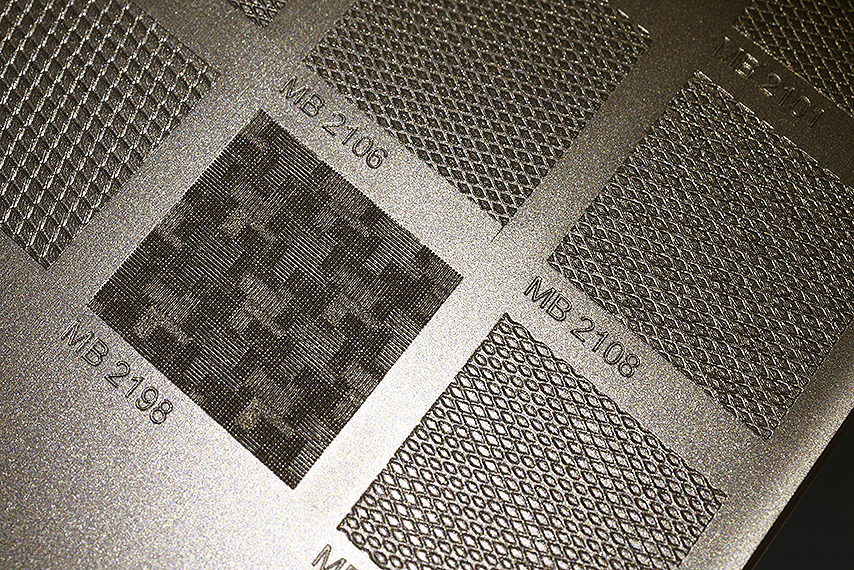

A class of their own. Steel positive models are lasered and the nickel shells are finished with mono- or two-tone gloss.

With the generation of 3D-LaserEngraving, which has been established at Krüth since 2009, it has become possible to develop sharp-edged, unusual, technical and organic engravings. Realising steel-positive models using 3D-LaserEngraving is easily achievable. The engravings are matched to them and specially developed as positive engravings. An upstream digital texture mapping process allows the engraving to be placed very precisely on the tool and virtually viewed before it is lasered. The next steps for creating a nickel shell are then identical to the series production process with a traditional leather foil. But that is not the end of the story. Once the nickel shell has been produced, it can be finished with a previously defined mono- or two-tone gloss. Process security and an aesthetic upgrade can thus be realised.

At KRÜTH, the digital engraving process is by no means the end of the story. High-quality surfaces can be finished with a mono or dual gloss.